A wood filler that makes your parquet look better and rework less

CosmetiWood is a ready-to-use industrial filler for oak and other species – designed together with parquet factories to reduce shrinkage, avoid “plastic dots” and keep your lines running smoothly.

Replace with a photo of your actual CosmetiWood sample kit (PRO / MAX, colours and knife).

A wood filler that makes your parquet look better and rework less

CosmetiWood is a ready-to-use industrial filler for oak and other species – designed together with parquet factories to reduce shrinkage, avoid “plastic dots” and keep your lines running smoothly.

Replace with a photo of your actual CosmetiWood sample kit (PRO / MAX, colours and knife).

PRO or MAX — which fits your line?

CosmetiWood PRO

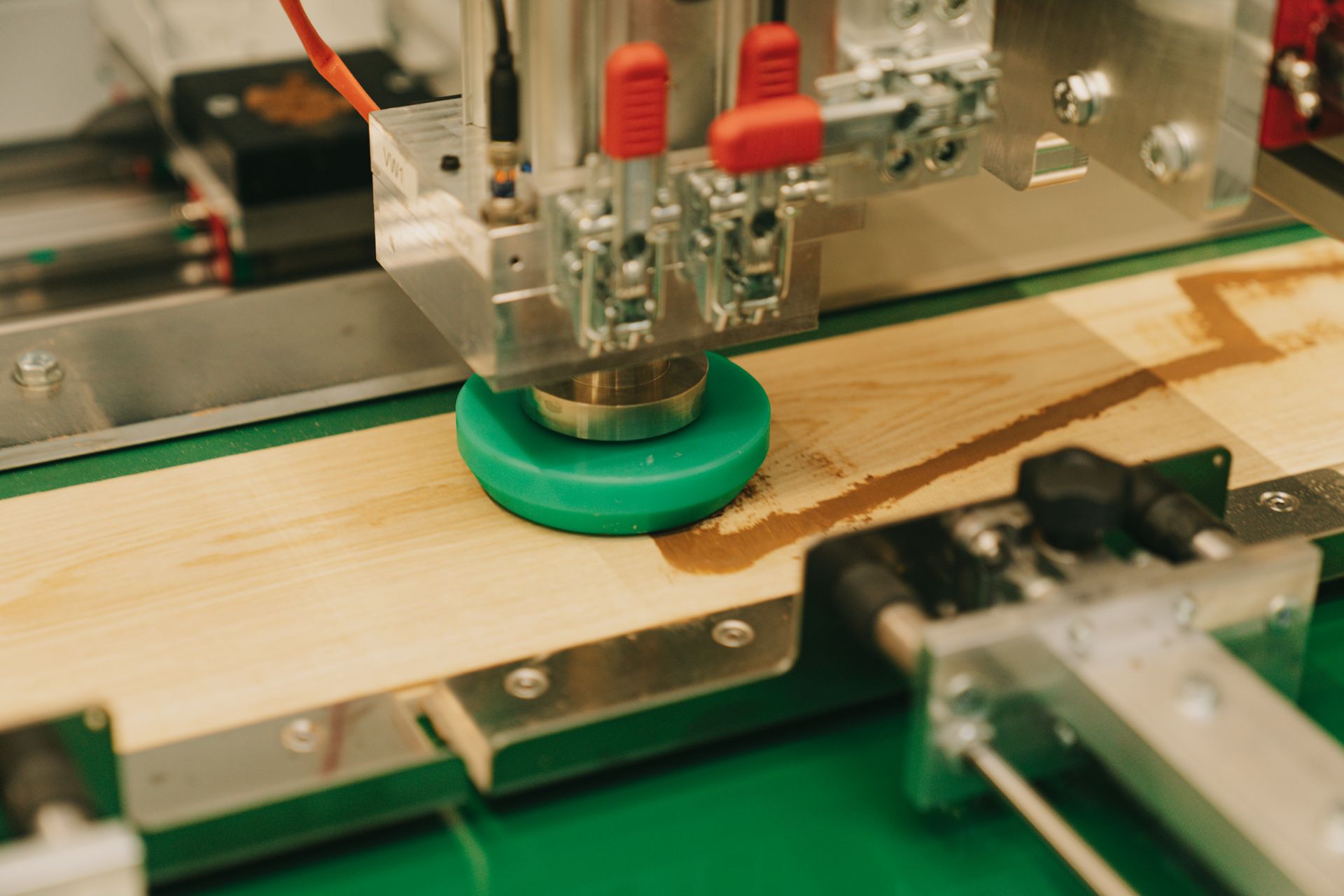

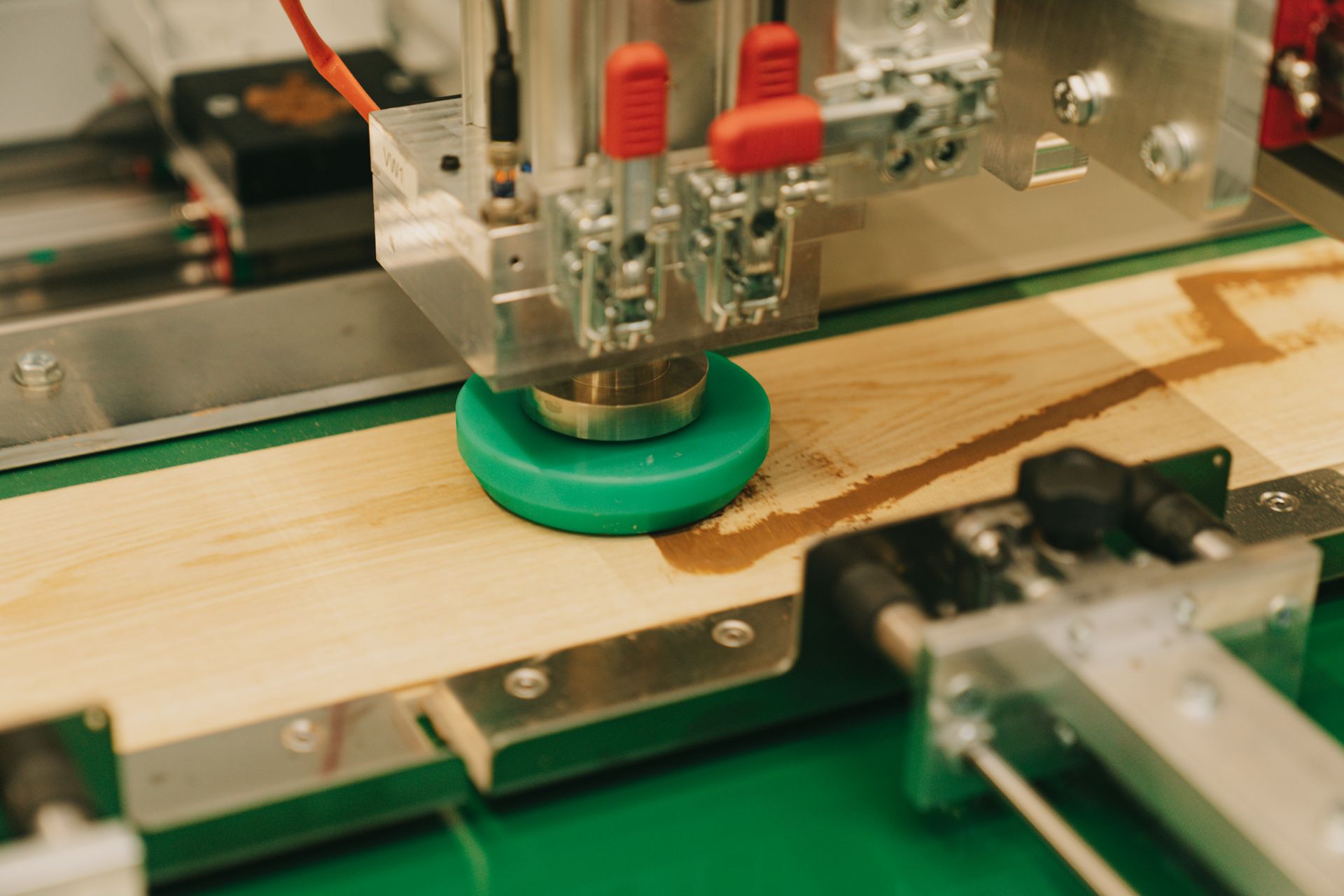

High-body, controlled filling

- Stays perfectly in place in larger knots.

- Very stable paste for fast lines.

- Ideal for machine (PAR-Filler) use.

CosmetiWood MAX

Creamier, easier to spread

- Flows easily into fine cracks.

- Very operator-friendly on the line.

- Great fit for manual workstations.

PRO or MAX — which fits your line?

CosmetiWood PRO

High-body, controlled filling

- Stays perfectly in place in larger knots.

- Very stable paste for fast lines.

- Ideal for machine (PAR-Filler) use.

CosmetiWood MAX

Creamier, easier to spread

- Flows easily into fine cracks.

- Very operator-friendly on the line.

- Great fit for manual workstations.

The CosmetiWood colour range

The tones most factories start testing with.

The CosmetiWood colour range

The tones most factories start testing with.

See exactly what you get with the CosmetiWood test kit

In one glance: what you decide, and what arrives on your desk.

How you want to test CosmetiWood

- Variants: CosmetiWood PRO, MAX or both in one kit.

- Colours: up to 6 tones that match your main oak ranges (natural, smoked, dark, grey, …).

- Shipping & line: where we ship and on which line you’ll run the test.

Takes less than 2 minutes to request. No obligation – purely for technical evaluation.

What’s in your CosmetiWood box

- Product: CosmetiWood PRO and/or MAX in the colours you selected.

- Samples: up to 6 pre-filled jars, clearly labelled.

- Tool: small filling knife / spatula for easy application.

- Guide: 1-page quick usage instruction for your operators.

Prepared for professional parquet & wood flooring manufacturers. A limited number of kits is assembled per month to ensure proper technical support.

See exactly what you get with the CosmetiWood test kit

In one glance: what you decide, and what arrives on your desk.

How you want to test CosmetiWood

- Variants: CosmetiWood PRO, MAX or both in one kit.

- Colours: up to 6 tones that match your main oak ranges (natural, smoked, dark, grey, …).

- Shipping & line: where we ship and on which line you’ll run the test.

Takes less than 2 minutes to request. No obligation – purely for technical evaluation.

What’s in your CosmetiWood box

- Product: CosmetiWood PRO and/or MAX in the colours you selected.

- Samples: up to 6 pre-filled jars, clearly labelled.

- Tool: small filling knife / spatula for easy application.

- Guide: 1-page quick usage instruction for your operators.

Prepared for professional parquet & wood flooring manufacturers. A limited number of kits is assembled per month to ensure proper technical support.

Four quick steps to test CosmetiWood on your own line

The kit includes a 1-page guideline – this video gives your operators a quick visual walkthrough.

Replace this image with a thumbnail of your instruction video once it’s ready.

Four quick steps to test CosmetiWood on your own line

The kit includes a 1-page guideline – this video gives your operators a quick visual walkthrough.

Replace this image with a thumbnail of your instruction video once it’s ready.

The key differences your test will reveal

Run CosmetiWood next to your current filler and look specifically at shrinkage, final appearance and how easy it is for operators to work with.

In many factories, these three points decide whether a filler can stay in production or not.

The key differences your test will reveal

Run CosmetiWood next to your current filler and look specifically at shrinkage, final appearance and how easy it is for operators to work with.

In many factories, these three points decide whether a filler can stay in production or not.

CosmetiWood is built to improve your line, not just your filler

Less rework & callbacks

Very low shrinkage and strong adhesion mean fewer boards returning from QC for refilling and sanding.

More natural-looking parquet

Fills knots and cracks without leaving shiny or plastic-looking spots after brushing and finishing.

Simpler, more stable process

Ready-to-use paste – no mixing or hardener. Fewer variables for operators, easier to control at scale.

CosmetiWood is built to improve your line, not just your filler

Less rework & callbacks

Very low shrinkage and strong adhesion mean fewer boards returning from QC for refilling and sanding.

More natural-looking parquet

Fills knots and cracks without leaving shiny or plastic-looking spots after brushing and finishing.

Simpler, more stable process

Ready-to-use paste – no mixing or hardener. Fewer variables for operators, easier to control at scale.

Request your CosmetiWood sample kit

Fill in the details below and we’ll prepare your personalised test kit, including your selected variants and colours.

Request your CosmetiWood sample kit

Fill in the details below and we’ll prepare your personalised test kit, including your selected variants and colours.